Printed Circuit Board (PCB)

Electrolytic Copper Foil

Steel Strip Plating EGL/ETL

General Metal Plating

Electro-Chlorination

Electro-Dialysis

Cathodic Protection

Electro-Oxidation

Applications

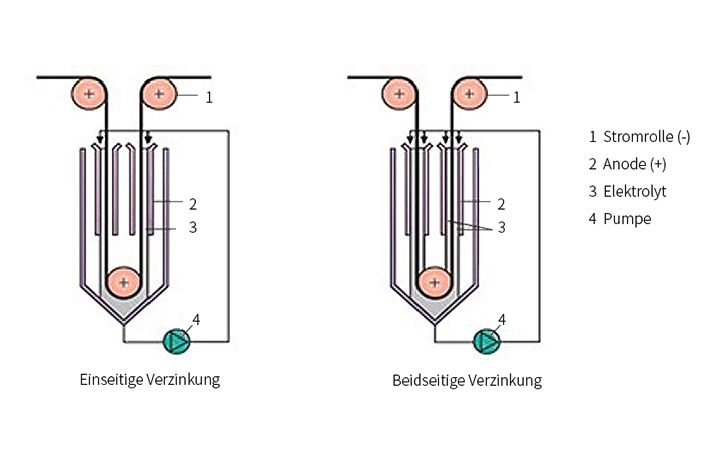

Electro-galvanized plate is characterized by good corrosion resistance, processability, weldability and painting, mainly used in automobile, home appliances, light industry and other industries. Electro-galvanizing products include double-sided, single-sided and differential coating depending on different coating; there are also passivation, phosphating, fingerprint proof and other products according to the different post-plating treatment.

Electro-galvanized plate is characterized by good corrosion resistance, processability, weldability and painting, mainly used in automobile, home appliances, light industry and other industries. Electro-galvanizing products include double-sided, single-sided and differential coating depending on different coating; there are also passivation, phosphating, fingerprint proof and other products according to the different post-plating treatment.

Electrolytic tinplate is mainly used in packaging industry thanks to its excellent corrosion resistance, beautiful appearance, high strength, light weight, good(deep stamping) formability, and good resistance to organic substance, dilute acid, alkali and salt corrosion. Tinplate products can be further divided into two categories: food (i.e. food packaging products) and general products (i.e. non-food packaging products).

Brief introduction of production process

After several pre-treatment processes, the cathodic strip will be treated in a series of electrolytic cells. The electrolytes in these cells contain soluble zinc or tin ions, which will be electrodeposited on the surface of the strip after electrochemical reaction.

Reaction mechanism

Anodic reaction(on anode surface): 2 H2O-4e →O2↑ + 4H+

Main cathodic reaction(on steel plate surface): Zn2++ 2e → Zn / Sn2++ 2e → Sn

Cathode surface reaction:: 2H2O + 2e → H2↑ + 2OH-