Printed Circuit Board (PCB)

Electrolytic Copper Foil

Steel Strip Plating EGL/ETL

General Metal Plating

Electro-Chlorination

Electro-Dialysis

Cathodic Protection

Electro-Oxidation

Background

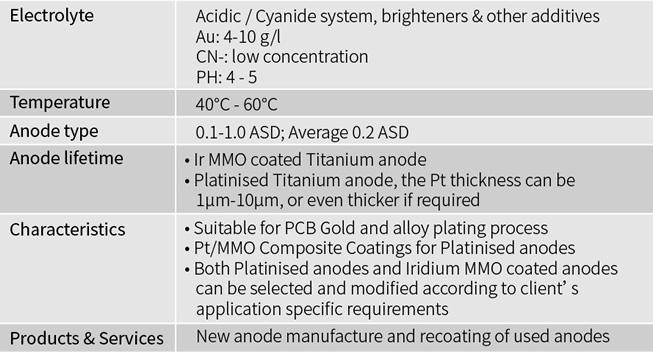

Plating a thin layer of nickel, tin, gold or alloy coating on electronics parts improves the electrical conductivity. For example the Ni/Au plating process is utilized in the PCB industry to improve the electrical performance of contact area with the purpose to obtain a low electrical contact resistance; good wear resistance and protection against oxidation (corrosion). MAGNETO special anodes can supply both Platinised anodes and Iridium Mixed Metal Oxide (MMO) coated Titanium anodes. The optimum anode coating depends on the client specific application requirements. Platinised anodes supplied by MAGNETO special anodes are already being widely used in these processes by various major manufacturers.

Plating a thin layer of nickel, tin, gold or alloy coating on electronics parts improves the electrical conductivity. For example the Ni/Au plating process is utilized in the PCB industry to improve the electrical performance of contact area with the purpose to obtain a low electrical contact resistance; good wear resistance and protection against oxidation (corrosion). MAGNETO special anodes can supply both Platinised anodes and Iridium Mixed Metal Oxide (MMO) coated Titanium anodes. The optimum anode coating depends on the client specific application requirements. Platinised anodes supplied by MAGNETO special anodes are already being widely used in these processes by various major manufacturers.

Application

Advantages

·Stable performance and long functional lifetime

·Low bath voltage and homogeneous current distribution

·Less additive consumption

·Environmentally friendly

·Low total cost of ownership