Printed Circuit Board (PCB)

Electrolytic Copper Foil

Steel Strip Plating EGL/ETL

General Metal Plating

Electro-Chlorination

Electro-Dialysis

Cathodic Protection

Electro-Oxidation

Application and process

Compared with hexavalent chromium plating, trivalent chromium plating is environmentally friendly, which makes the demand for trivalent chromium plating increase year by year. In the process of trivalent chromium plating, it is very important to prevent the oxidation of Cr3+ to Cr6+ and avoid pollution to bath solution. Traditional lead-base alloy anode or graphite anode is not suitable for trivalent chromium plating due to its high oxygen evolution potential. The titanium anode with iridium mixed metal oxide coating has low oxygen evolution potential, which effectively inhibits the oxidation of Cr3+ and ensures the stability of the plating solution. Moreover, titanium anode characterized by excellent conductivity, uniform current distribution and excellent electrolyte corrosion resistance is the best conductive electrode for trivalent chromium plating.

Compared with hexavalent chromium plating, trivalent chromium plating is environmentally friendly, which makes the demand for trivalent chromium plating increase year by year. In the process of trivalent chromium plating, it is very important to prevent the oxidation of Cr3+ to Cr6+ and avoid pollution to bath solution. Traditional lead-base alloy anode or graphite anode is not suitable for trivalent chromium plating due to its high oxygen evolution potential. The titanium anode with iridium mixed metal oxide coating has low oxygen evolution potential, which effectively inhibits the oxidation of Cr3+ and ensures the stability of the plating solution. Moreover, titanium anode characterized by excellent conductivity, uniform current distribution and excellent electrolyte corrosion resistance is the best conductive electrode for trivalent chromium plating.

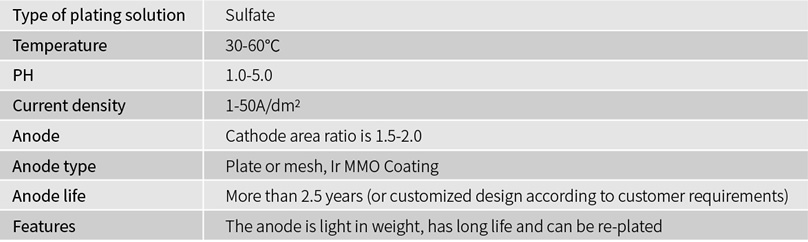

Typical application conditions

Advantages

Promote the dispersion of metal coating

No or less Cr6+ ions are generated, to avoid the pollution of bath solution

No anode slime is generated, to ensure the cleanness and stability of the plating solution

Low voltage, high current efficiency, energy saving of plating bath

Good corrosion resistance and thermal shock resistance.