Printed Circuit Board (PCB)

Electrolytic Copper Foil

Steel Strip Plating EGL/ETL

General Metal Plating

Electro-Chlorination

Electro-Dialysis

Cathodic Protection

Electro-Oxidation

Background

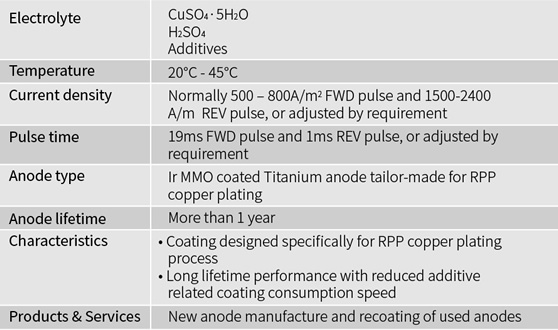

The design requirements for printed circuit boards are moving to multi-layered low thickness circuit, high current density, reduced thru-hole diameter and miniaturized via filling whilst production speeds are increasing. To address these challenges, reverse pulse plating and continuous DC plating with special chemical additives have been developed. Nevertheless, both DC plating and reverse pulse plating suffer from the problem of soluble copper anode passivation in high current density. However, the insoluble, Iridium Mixed Metal Oxide (MMO) coated Titanium anodes will not be passivated even under very high current densities. Next to that, in the RPP copper plating process, requirements for Titanium anode are specific and demanding, such as a big current density range operating window, constant polarization and RPP wave form transfer, and stable plating additive consumption rates. As for standard MMO coated anodes the plating additives also would influence the anode coating consumption rate and with that a homogeneous current output, only specially designed high quality Titanium anodes with special modified Iridium MMO coatings can work under these conditions.

The design requirements for printed circuit boards are moving to multi-layered low thickness circuit, high current density, reduced thru-hole diameter and miniaturized via filling whilst production speeds are increasing. To address these challenges, reverse pulse plating and continuous DC plating with special chemical additives have been developed. Nevertheless, both DC plating and reverse pulse plating suffer from the problem of soluble copper anode passivation in high current density. However, the insoluble, Iridium Mixed Metal Oxide (MMO) coated Titanium anodes will not be passivated even under very high current densities. Next to that, in the RPP copper plating process, requirements for Titanium anode are specific and demanding, such as a big current density range operating window, constant polarization and RPP wave form transfer, and stable plating additive consumption rates. As for standard MMO coated anodes the plating additives also would influence the anode coating consumption rate and with that a homogeneous current output, only specially designed high quality Titanium anodes with special modified Iridium MMO coatings can work under these conditions.

Application

Advantages

·Suitable for reverse pulse plating(RPP)

·Excellent throwing power

·Exceptional copper thickness uniformity

·High current efficiency performance

·Environmentally friendly

·Low total cost of ownership